Research & Development

See the latest innovations our scientists, engineers, and researchers have been working on Request Product DataWe're committed to extending the reach of water and wastewater treatment through technological advances

At Fluence, we're working to create a better world through ongoing technological innovation. We're embracing sustainability, economy, and flexibility in our quest to provide clean water wherever it's needed around the world. We strive for excellence through innovation and technological leadership, and our intellectual property is an important aspect of that: Our patents extend across a wide range of treatment equipment and processes.

We believe that the emerging concept of distributed, or decentralized, water management is the key to water sustainability, providing the right water treatment at the point of use, at the right scale -- and at the right price. Recent developments in treatment, automation, remote control, and communication technologies are allowing us to break new ground with systems that lower infrastructure and operating costs and maximize flexibility. Our Smart Packaged water and wastewater treatment solutions take advantage of these innovations to make treatment even more viable.

We're also working to standardize essential features of wastewater treatment to allow for consistent specification of energy consumption and efficiency.

Rigorous Research and Testing

Fluence's R&D center in Israel is the biggest MABR research facility in the world, including pilots and experiments for existing and future product lines. The research center includes a dedicated laboratory equipped with all the sampling equipment necessary to test water and wastewater for BOD, COD, TSS, VSS, TN, TKN, TP, NH4+, NO3, NO2, conductivity, pH, dO2, ORP, and more. Several small-scale pilot plants running at the research center continually test MABR treatment under a range of streams and loads, providing information for small to larger-scale commercial sites.

Some of these pilots have included five in China in 2016, one in the CENTA research center in Spain, and one in 2018 at Stanford University's Codiga Resource Recovery Center in California, which tested MABR systems with very concentrated wastewater streams. The plants reduced the loads to very strict effluent criteria, meeting and exceeding regulations in China and in California, which has some of the most stringent in the United States.

Fluence is currently conducting several collaborative research programs:

- Investigating water reuse in agriculture under the Horizon 2020 PRIMA program, as part of the DSWAP consortium

- Researching side-stream treatment with a U.S. company under a binational U.S.-Israel grant

- Improving the efficiency of energy recovery as part of a U.S.-Israel consortium dealing with the water-energy nexus

We are constantly looking for interesting partnerships for development of new and improved treatment process technologies. Please contact [email protected] with any inquiries.

Optimizing Nutrient Removal With MABR

Revolutionary wastewater treatment technology optimizes nutrient removal while slashing energy requirements

In the field of biological wastewater treatment, Fluence has invested years of research and development into the innovative and energy-efficient membrane aerated biofilm reactor (MABR), which provides exceptional nutrient removal while minimizing energy use, making treatment possible even off the grid.

Fluence's MABR uses a proprietary, spirally wound membrane for maximum treatment surface area and optimization of several processes, including simultaneous nitrification-denitrification (SND).

After 7 years of researching and manufacturing MABR membranes, continual improvement remains at the top of our agenda. We have built research stations and are testing different types of materials, packaging forms and other membrane properties to optimize our product for the next generation of MABR.

For example, Fluence is operating a full-scale pilot plant to test the technology's performance in cold climates, as well as developing a smart control system that will allow for SND in MABR-free basins, producing superior effluent quality with minimum energy usage.

One of the first MABR pilot modules we created more than six years ago has been running nonstop ever since under a variety of conditions to test its durability. We have dried it, flooded it, and fed it a wide variety of wastewater streams, and it has continued to do its job!

This revolutionary technology is available in stand-alone plants, as well as in towers that can be used to retrofit existing wastewater treatment plants.

MABR Benefits

Fluence's membrane aerated biofilm reactors:

- Feature simultaneous nitrification and denitrification for optimized nutrient removal

- Use up to 90 percent less energy than conventional treatment, cutting operating expenses in half

- Are quiet and odorless, making them neighborhood-friendly

- Have lower requirements for an external carbon source

- Require no internal circulation for nitrogen removal

MABR products in our research center include...

Aspiral™ L

Aspiral™ S

Aspiral™ MBR

SUBRE

Calculating Energy Use With ISO 21939

The new international standard gives engineers and operators a universal way to calculate energy consumption

In today's environment, energy consumption is an increasingly important consideration in efficient wastewater treatment plant design. The energy consumed by biological treatment processes significantly impacts operational costs and environmental footprints.

ISO 21939-1:2019 introduces a standardized means to express energy consumption for biological wastewater treatment processes. This method accounts for all pollutants and normalizes the calculation of energy consumed to allow meaningful comparisons among facilities and technologies.

Fluence supports ISO 21939. In order to give a more accurate evaluation of process energy use, Fluence uses Normalized Energy Consumption calculations in accordance with the new standard. Learn more here.

Turning Waste Into a Resource

Fluence Italy’s R&D team has a track record of developing groundbreaking waste-to-energy solutions

For more than 20 years, the experienced research and development team at Fluence Italy has had a focus on waste-to-energy technology, particularly anaerobic digestion in wastewater treatment. With two semi-industrial plants in addition to laboratory-scale digesters, Fluence Italy can thoroughly evaluate processes to offer the best solutions to clients. Highlights of the team's work include:

- Groundbreaking research on the continuous stirred tank reactor (CSTR), which positioned the company as the leader in Italy for anaerobic digestion of wastewater and by-products from industries including meat, fish, and dairy, and more recently the pharmaceutical and biorefinery industries.

- Optimization of the granular sludge rapid digester in a processor known as the up-flow anaerobic sludge blanket (UASB), with further refinements including the proprietary external forced circulation (EFC) reactor, which allows treatment of highly diluted effluent from breweries, paper mills, and confectionaries.

- Thermophilic anaerobic digestion. With this solution, plants work at a higher temperature, allowing an increase in biogas production by almost 70% while maintaining the same footprint. This application is particularly successful in the dairy sector.

- Collaboration with the University of Padua on anaerobic ammonium oxidation (Anammox). This post-treatment of digestate with a high nitrogen content reduces energy consumption and the need for external carbon sources for treatment.

- Hydrolysis processes that lead to a reduction of digested sludge and an increase in biogas production.

Waste-to-Energy Resources

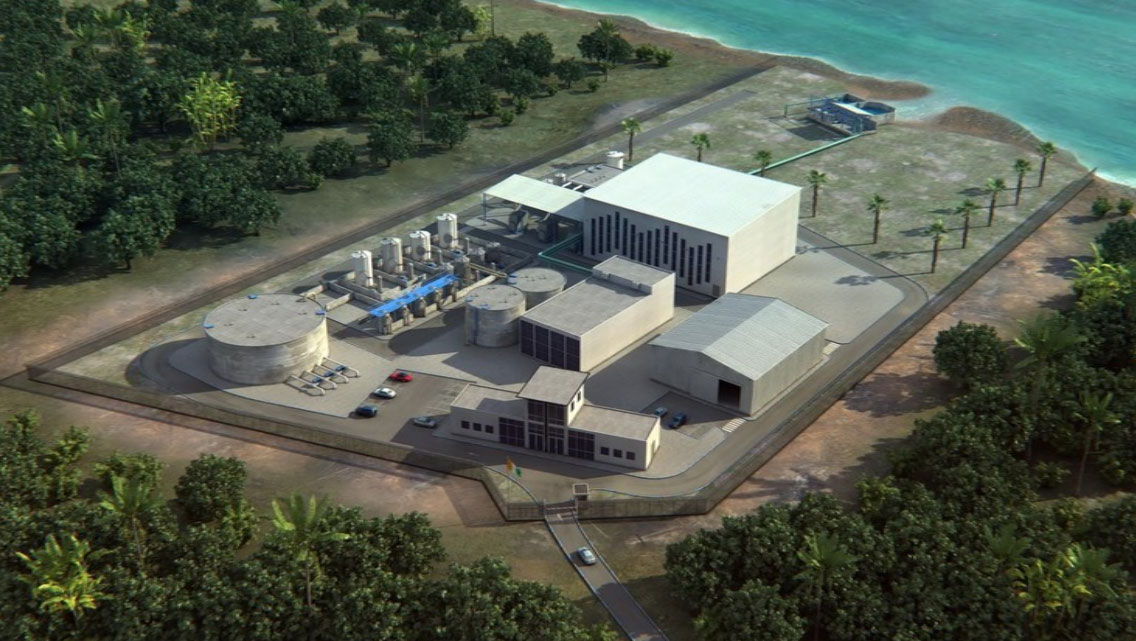

Containerized Desalination

Specially engineered processes yield high-capacity seawater desalination in standardized, compact units

Emerging Contaminants

Removing microplastics and other hard-to-treat pollutants to produce high-purity water for industry

Toxic Algae

Toxic algal blooms make water unsafe, but Fluence has solutions to make water safe for irrigation and drinking

Are you looking for cutting-edge solutions for your water and wastewater treatment needs? At Fluence, our experts can help you find the ideal technology to meet your requirements, with an emphasis on economy and sustainability. For more information about any of our ongoing research projects, please email [email protected].