MABR Wastewater Treatment

Learn more about Fluence's best-in-class MABR solutions REQUEST A QUOTESEE BENEFITSFluence's revolutionary membrane aerated biofilm reactor (MABR) technology features highly efficient biological nutrient removal

Backed by years of research and more than 200 commercial projects, MABR is the wastewater technology of the 2020s. Reaching new treatment efficiency records in small- to medium-sized wastewater projects, the MABR product family provides a complete solution range for both new and upgrade projects.

Unique Biological Process

Activated sludge treatment has long been used for aerobic wastewater treatment, but its aeration stage is particularly energy-intensive, and as a result, expensive.

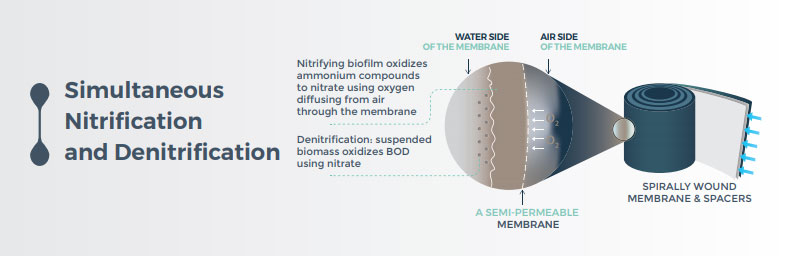

Fluence's self-respiring membrane aerated biofilm reactors (MABRs) provide an energy-efficient alternative that provides a very high quality effluent. MABR technology is based on passive aeration, that is, the diffusion of oxygen through membranes.

During the process, oxygen is constantly supplied to the fixed nitrifying biofilm that develops on the wastewater side of the membrane while denitrification occurs in the anoxic bulk liquid. The unique MABR process provides highly efficient biological nutrient removal, resulting in operational savings and minimal footprint requirements that make decentralized treatment more feasible.

Our MABR Solutions

Wastewater Treatment for Every Need at Any Scale

For maximum flexibility, Fluence offers MABR technology in two versatile formats: Our Aspiral™ Smart Packaged line is available in a variety of capacities, and our SUBRE line is used to upgrade existing aerobic wastewater treatment plants, cutting energy costs, and increasing capacity or improving effluent quality.

Aspiral™ Smart Packaged Wastewater Solutions

Aspiral small- to medium-sized Smart Packaged MABR plants are ideal for serving small towns, villages, residential communities, resorts, and more. Aspiral's efficiency makes it suitable for decentralized treatment off the grid since its low energy needs can be supplied by alternative sources.

Aspiral is available in several model sizes and configurations, with treatment capacities starting at 20 m³/d, depending on effluent requirements and design temperature. Several containers may be connected in tandem to handle large quantities of effluent. For operating ease, the systems can be remotely monitored and controlled.

Learn more about Aspiral™ Smart Packaged Wastewater Solutions.

SUBRE Wastewater Treatment Upgrades

When a conventional activated sludge wastewater treatment facility has reached its limit, Fluence's SUBRE can come to the rescue. SUBRE, which uses membrane aerated biofilm reactor (MABR) towers, is designed to upgrade existing basins with capacities of 2,000-100,000 m³/d (0.5-22 MGD).

Instead of enlarging current plants and building new basins, SUBRE towers are submerged in existing chambers, improving effluent quality, lowering the use of chemicals, saving energy and operational costs, and increasing capacity.

Learn more about SUBRE MABR wastewater treatment plant upgrades.

MABR Provides Simple, Energy-Efficient Wastewater Treatment Wherever It’s Needed

Small- to medium-capacity MABR systems from Fluence save up to 90% on energy used for aeration, compared to conventional plants. MABR's energy efficiency means it can be operated with alternative energy sources off the grid, making it ideal for decentralized treatment.

Whether you need a new wastewater treatment system or want to upgrade an existing plant, Fluence can help. Contact our experts to learn more about how MABR-based treatment can save money and increase effluent quality.

What Is MABR?

Membrane aerated biofilm reactor (MABR) technology provides a revolutionary improvement in aerobic wastewater treatment due to its highly efficient nutrient removal and its energy efficiency, compared to traditional wastewater treatment systems.

MABR Benefits

High Effluent Quality

Simultaneous Nitrification and Denitrification

Energy Efficiency

Low Maintenance and Operation Costs

Low Odor and Noise

Flexibility and Scalability

Upgrade Wastewater Treatment Plants with SUBRE

With increased urbanization, wastewater resource recovery facilities face new challenges

When a conventional activated sludge wastewater treatment facility has reached its limit, Fluence's SUBRE can come to the rescue. Instead of enlarging current plants and building new basins, SUBRE modules are submerged in existing chambers, improving effluent quality, lowering the use of chemicals, saving energy and operational costs, and enlarging capacity. SUBRE upgrades WWTPs using membrane aerated biofilm reactor (MABR) modules. SUBRE is designed to upgrade existing basins with capacities of 2,000-100,000 m3/d (0.5-25 MGD) or improve effluent qualities to meet stringent nutrient regulations.

SUBRE enables:

- Increased treatment capacity to accommodate higher inflows

- Reduced TN and TP in effluent water (biological nutrients removal)

- Progress toward energy-neutral treatment

In a SUBRE upgrade, The SUBRE modules containing up to 4 levels of MABR spirals are submerged in the anoxic zone of the WWTP (in a fully aerated reactor with no anoxic zone, construction of a separating wall will be required).

Easy-to-install MABR modules are energy-efficient and cost-effective, and ensure high effluent quality due to simultaneous nutrients revmoal. The SUBRE modules are suitable for installation in basin depths ranging from 1.5 m to 6 m (5-20 feet). The modules are anchored to the basin floor and are aerated by a separate low-pressure low-flow blower. Coarse bubble diffusers are used for periodic mixing of the suspended biomass (utilizing existing aeration blowers if possible).

The retrofit can be performed with minimal interruption, one basin at a time. Results seen in one to three weeks include an improved effluent quality and up to a 30% decrease in the plant's overall energy use. And, SUBRE will greatly save on operational expenses.

The SUBRE upgrade will achieve

- Enhanced Nitrogen removal

- Enhanced Bio-Phosphorous removal

- Increased capacity

- Improved effluent quality

- Decrease operational costs by up to 30%.

MABR Modules outperform attached growth solutions such as MBBR and IFAS with:

- Higher nitrification rate achieved in a once-through process

- Enhanced Biological Phosphorus removal

- Reduced energy costs

- Lower chemicals usage.

Are you looking for ways to get more from your existing wastewater treatment plant? Contact our experts at Fluence for more information on how you can increase capacity, cut energy use, and improve effluent quality with SUBRE MABR modules.

SUBRE FEATURES AND BENEFITS

- Upgrades existing WWTPs with basin capacities of 2,000-100,000 m³/d (0.5-25 MGD)

- Available in arrays of one to four MABR spirals per modules

- Ideal for expanding treatment capacity of plants without expanding footprint

- Up to 80% TP removal in biological stage

- Stable effluent quality complies with stringent regulations

- Up to 20% OPEX reduction

- Reduced carbon addition by up to 30%

- Full technical support and membrane warranty

- Zero footprint - no additional construction

- Simple to operate

- Progress toward energy-neutral treatment

Featured MABR Case Studies

Smart Packaged Aspiral™ MABR for Highway Service Area

Four Aspiral™ MABR Systems in Rural China