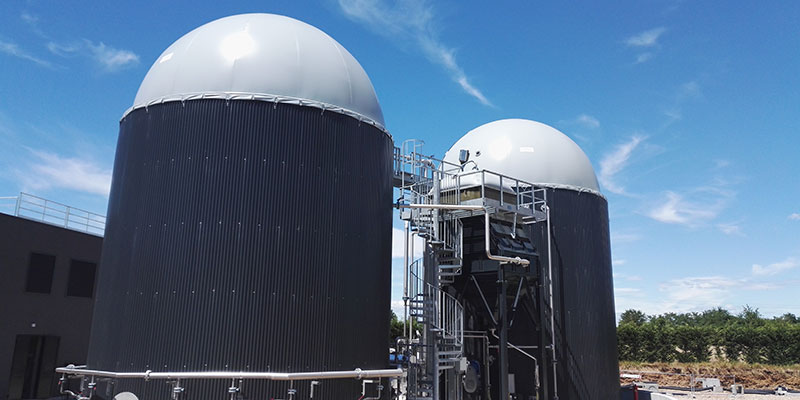

Wastewater effluents from food production are treated in an external forced circulation (EFC) anaerobic reactor, producing clean water for reuse and generating operating power.

EFC reactors bring many advantages for treating high COD wastewater

The external forced circulation (EFC) reactor is a type of anaerobic digester developed by Fluence that is particularly suited for the treatment of high soluble COD wastewater streams like those of:

- Paper and pulp manufacturing

- Livestock operations and slaughterhouses

- Meat and seafood processing and packaging

- Confectionary manufacturing

- Fruit processing

- Dairy product manufacturing

The EFC offers distinct advantages over the up-flow anaerobic sludge blanket (UASB) reactor from which it evolved. Operations that upgrade to an EFC reactor system can expect to increase their biogas yields, increase flow rates, decrease the amount of sludge that must be disposed of, and produce high-quality effluent that can be reused.

Higher Flow Rates

The EFC reactor is operated by creating an external recirculation system where specific-sized granular sludge is recirculated and mixed with the main influent. A specialized decanter process is utilized to capture specific-size granular sludge for recirculation or removal. In this way, the hydraulic retention time (HRT) is decoupled from the solids retention time, meaning small reactor volumes can be utilized. Most EFC reactors can operate with less than one day of HRT, making the process cost-effective and space-efficient. EFC is often the preferred high-rate anaerobic technology for treating high-flow primary effluents.

Reduced Sludge Production

The EFC reactor enhances biogas production significantly, for a level-up in sustainability, and produces less sludge than other anaerobic digestion methods, reducing the volume of waste that needs to be disposed of. Recirculation of granular sludge biomass helps to maintain higher process stability, reducing process upsets and sludge disposal. Fluence’s EFCs typically discharge less than 250 mg/L of total suspended solids (TSS).

By adding anaerobic digestion to an Italian confectionary producer’s wastewater treatment, Fluence helped improve effluent and produce energy.

When Dolcissimo SRL, a confectionary in France, wanted to maintain high effluent standards and add waste-to-energy to its wastewater treatment, Fluence provided a hybrid solution to deal with its high-COD effluent. Fluence combined a classic CSTR sludge digester with an EFC reactor and a desulfurization solution, reducing COD from 9,600 mg/L to less than 80 mg/L and nitrogen from 115 mg/L to less than 10 mg/L, and lowering solid sludge by 70%.

Environmental Sustainability

Anaerobic digestion is arguably the most successful form of resource recovery in terms of the value of the products recovered and environmental benefits. Biogas is a carbon-neutral fuel, and every unit of biogas recovered to produce energy represents a unit of fossil fuel that can remain in the ground.

Wastewater effluents from food production are treated in an external forced circulation (EFC) anaerobic reactor, producing clean water for reuse and generating operating power.

Italcanditi-Vitalfood, a major candied fruit producer in Northern Italy, wanted to double production while cutting costs. Generating biogas was the answer, but adding it was a challenge due to limited space and a strict production schedule. Fluence designed an EFC reactor system that was installed in the available space without interrupting production. The system produces 4,800 m3/d of biogas for a savings of $400,000 a year.

Another important resource recoverable from wastewater is the water itself. EFC reactor-based systems produce an effluent that can be reused for a wide range of nonpotable applications. That’s important for water efficiency and resilience to climate shocks.

Higher yields of carbon-neutral fuel. Superior water purification. Less sludge disposal. The compounding advantages of EFC reactors make it an attractive solution for high COD wastewater. Contact Fluence to explore the industry-leading performance of the EFC reactor.