NIROFLEX's flexibility allows for a solution custom-fitted to your needs

With a series of standardized units for pretreatment filtration and reverse osmosis desalination -- as well a range of optional features -- Fluence can quickly and economically build a desalination plant that fits your requirements for capacity and water quality.

Fluence has a proud history of providing water and wastewater solutions where they're needed, with the belief that everyone deserves access to clean water. To add to the company's array of desalination solutions, Fluence's water experts have designed a family of pre-engineered building blocks that can be assembled into cost-effective seawater desalination systems that match any water sourcing need.

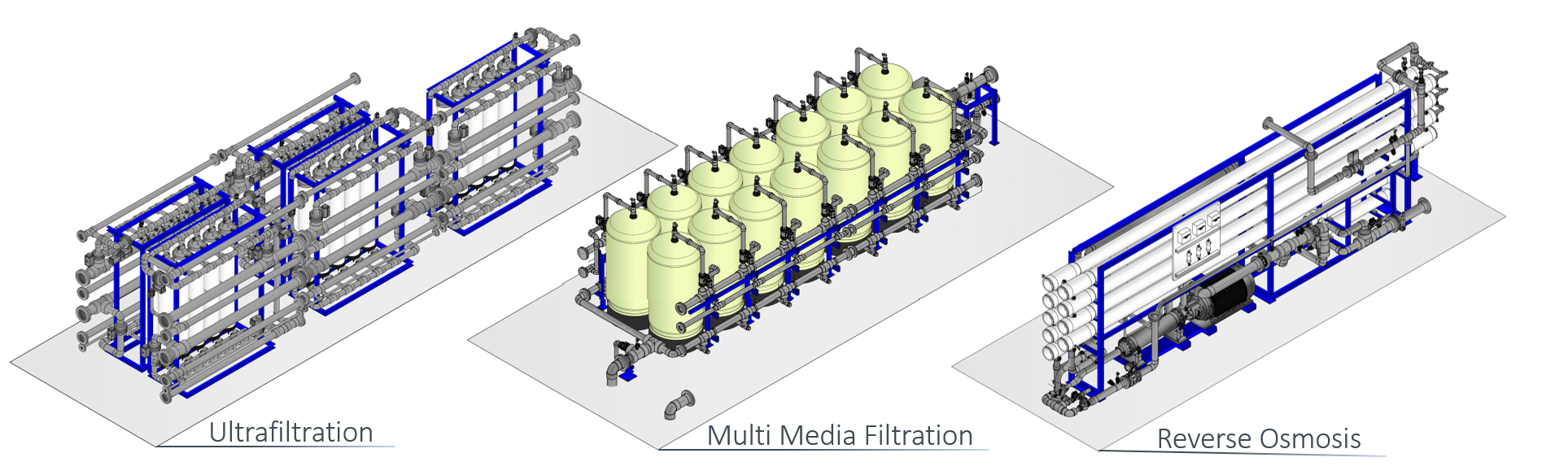

Developed from the highest quality standard components, NIROFLEX includes blocks for reverse osmosis, as well as pretreatment blocks for ultrafiltration and multimedia filtration. The versatility of the Niroflex system means the blocks can be arranged for capacities that produce from 100 m³/d (25,000 GPD) up to 15,000 m³/day (3.75 MGD) of clean water.

Reverse Osmosis

- A positive displacement pump combined with an isobaric exchanger for low energy consumption and constant capacity in a wide range of temperatures

- A centrifugal pump combined with a turbocharger, for lower CapEx investment

Pretreatment

- Multimedia filter systems that produce up to 7,200 m³/d (1.9 MGD), with low CapEx investment, simple operation, and low chemical requirements

- An ultrafiltration system that produces up to 6,200 m³/d (1.6 MGD), with high filtration ratings that correspond to long RO membrane lifecycles and a high rejection of total organic compounds (TOC)

Optional Features

- Integrated cleaning in place (CIP) with an automatic flushing system

- Compressor with air dryer

- Feed pumping station

- Alternative power supply

- Remineralization

- Delivery pumping station

- Remote monitoring software with cloud-based data logging

- High scalability

DESALINATION CHALLENGES?

Featured Desalination Case Studies

NIROBOX™ SW Units for a Costa Rican Resort

NIROBOX™ Desalination Plant in Africa