By adding anaerobic digestion to an Italian confectionary producer’s wastewater treatment, Fluence helped improve effluent and produce energy.

Anaerobic digestion, used to produce biogas, also improves wastewater treatment effluent

A new report, “Market states and trends in renewable and low-carbon gases in Europe,” shows that many European companies are adopting biomethane, a sustainable fuel that is produced by biogas derived from organic matter. The report was published by Gas for Climate: A Path to 2050, a group of 10 leading European gas transport companies and two renewable gas industry associations.

In the European Union (EU), biomethane adoption is fully underway. In 2011, the European Commission (EC), a branch of the EU, set a goal to fully decarbonize its economy by 2050. At the end of 2019, the EC announced its Green Deal, setting an interim goal to reduce greenhouse gas emissions by 55% (from 1990 levels) by 2030. To succeed, electricity and gas sectors will need to cooperate to hit a host of targets, from novel technology adoption to grid upgrades.

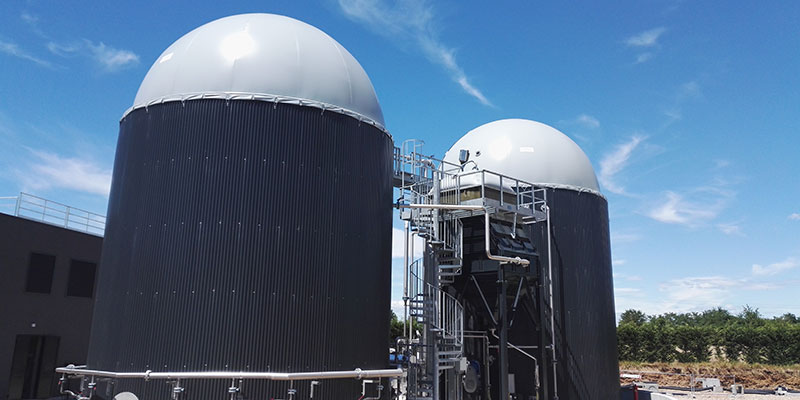

Producing Fuel With Anaerobic Digestion

An important factor in reaching these goals is the use of alternative energy sources including biogas and biomethane, a more highly purified form of biogas. The most common way to produce biogas is a waste treatment method called anaerobic digestion (AD). In waste-to-energy AD, a feedstock such as sewage is digested in a tank outside of the presence of air, and the resulting biogas can be used as fuel. Purification of biogas, by processes including membrane separation, yields biomethane. Both products are in use as fuel in the EU, but use of biomethane is growing faster than use of biogas.

While many of the competing decarbonization strategies analyzed in the report are considered merely promising or in the early-trending stages, biomethane is considered to be fully trending, on target with 2050 goals, and it’s expected to continue growing. For instance, an astonishing 17% of road transport in the EU is already powered by biomethane, and cross-border trade in the gas is increasing. The use of waste and residue feedstock for anaerobic digestion also is increasing, a trend that’s expected to continue.

Anaerobic digestion is a robust realization of the waste-to-energy model, the resource recovery model, and the circular economy, trends that are becoming more popular among decision makers around the world.

Anaerobic Digestion Plant Size

In the EU, anaerobic digesters range in size from small local plants, at approximately 100 Nm³/hr (~0.2 Mwel biogas output), to greater than 3,000 Nm³/hr (~6.2 Mwel biogas output) for large industrial plants, according to the report. The size of the plants has been trending upward as waste streams are cooperatively combined to leverage economies of scale.

But even in EU regions where there is not enough waste to justify large digesters, smaller plants are realizing bottom line benefits from installing anaerobic digesters.

While digester size and lower feedstock volume were limiting factors in the past, a Fluence advance is helping smaller operations surpass the break-even point. Previously, small operations without sufficient feedstock for cost-efficient biogas recovery developed relationships with other entities, pooling feedstock and digesting them in the same reactor, a practice called co-digestion. With the external forced circulation (EFC) reactor, however, smaller operations can produce biogas with no need to pool feedstock.

The EFC reactor is an iteration of anaerobic digestion developed from the up-flow anaerobic sludge blanket (UASB) reactor, a high-rate system that already has lower hydraulic retention times than other anaerobic digestion processes. EFC technology improves on the UASB process by adding an external pumping system to recirculate the granular sludge biomass across an enlarged bed, increasing contact between the wastewater and the sludge.

The result is efficient biogas production with short retention times of six to 48 hours. High-rate EFC reactors can now provide an economical solution for smaller operations that want to reap the benefits of sustainable biogas production.

In Italy, for example, a confectionery manufacturer turned to Fluence to add an anaerobic digestion system to its wastewater treatment to both treat its high-COD wastewater and recover energy at the same time.

Beyond Waste-to-Energy

Anaerobic digestion also produces other bottom line and environmental benefits. First, it can handle difficult-to-treat wastewater streams with a high nutrient load. Cleaner effluent solves disposal problems, lowering bills from local wastewater treatment utilities, and even allowing for environmental discharge. The organic digested biosolid that remains after AD is valuable to agriculture for soil amendment, and nitrogen can be recovered during anaerobic digestion to make concentrated fertilizer.

Contact Fluence, a global company with decades of experience operating in the EU, to learn more about turning your wastewater stream into a revenue stream, while moving toward carbon-reduction goals.