The biofilm that forms on the membrane used in Fluence’s MABR technology allows nitrification and denitrification to take place simultaneously in the same tank.

MABR’s simultaneous nitrification and denitrification process means wastewater treatment can take place in a single tank

A membrane aerated biofilm reactor (MABR) is a revolutionary wastewater treatment technology that improves nutrient removal and cuts the energy requirements of the aeration cycle by as much as 90% compared to legacy activated sludge systems.

MABR’s efficiency means treatment can take place with a smaller footprint, making it well-suited for modular, decentralized treatment options.

What Is Biofilm?

What exactly is biofilm and what role does it play in this process?

A biofilm is a natural colony of microorganisms (such as bacteria, fungi, or protists) that loosely attach to a surface and then bond to it. They grow, layer upon layer, in a slimy, protective matrix of biopolymers called extracellular polymeric substances (EPS). They thrive on a wide variety of moist or wet surfaces, colonizing everything from mineral and metal surfaces to plant and animal tissues, on land or in bodies of water.

The microorganisms signal one another chemically within the complex, three-dimensional structures of the mature biofilm, which becomes internally latticed with water channels that the microorganisms use to exchange nutrients and waste products. This natural process can clean wastewater.

Harnessing Biofilm for Wastewater Treatment

MABR technology uses a biofilm, with its sophisticated structures and defenses, to treat wastewater efficiently and organically.

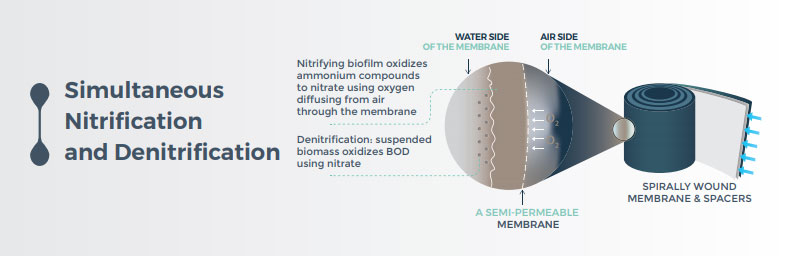

Fluence’s MABR modules contain a spirally wound, semipermeable membrane submerged in mixed liquor. Spacers allow the two-layer membrane to form an envelope of air that feeds aerobic organisms. A biofilm that grows on the surface of the membrane maintains simultaneous nitrification and denitrification (SND), which offers several benefits for wastewater treatment.

In both MABR and traditional activated sludge processes, denitrification is the final goal. In traditional activated sludge treatment, nitrification takes place in one step, then denitrification occurs in deep-bed, monomedia filters. Methanol or another carbon source is added to nourish denitrifying bacteria in the filters. To activate the process, traditional treatment requires pumping compressed air into the wastewater which uses a great amount of energy. Only about 10% of the bubbles reach the microorganisms, while the other 90% escape.

MABR is much more efficient. Air is conveyed directly through the membrane at near-atmospheric pressure and it naturally moves through the system, creating an ideal environment for bacteria that soon form the biofilm that converts ammonia in the wastewater into nitrate. This process saves energy since it does not require expensive air compression.

With MABR, wastewater in parts of the tank is anoxic enough that nitrate can convert into nitrogen gas in the same tank. It is then released into the atmosphere with no environmental impact. So, a job that once required separate compartments takes place simply, simultaneously, and efficiently in a single tank, allowing MABR to treat more effluent to a higher quality on a smaller footprint.

Advantages of the MABR for Decentralized Treatment

A number of advantages make MABR ideal for decentralized treatment. They are made possible by the powerful biofilm that does more in less space, so treatment can be packaged for unprecedented portability. Fluence’s Aspiral™ line of Smart Packaged MABR units has proved to be a reliable component of a decentralized wastewater treatment strategy, with a number of benefits, including:

- MABR’s low energy requirement makes it possible for Aspiral to operate off-grid using alternative energy sources.

- Aeration is contained resulting in an unobtrusive, low-odor, low-noise system that doesn’t disturb neighbors or tourists.

- Compact MABR units are easily located out of sight, leaving scenery undisturbed.

Powerful but compact Aspiral MABR units are furnished in standard shipping containers for easy transport, and little construction or site preparation is required. They can be placed right where they are needed.

Aspiral units are well-suited for urban or industrial settings, remote workforce housing, rural schools and institutions, as well as small island developing states and tourist destinations.

Retrofitting Existing Plants with MABR

Fluence SUBRE MABR towers can be submerged in existing infrastructure to increase both capacity and the quality of effluent.

In summary, Fluence engineering has created the ideal environment for biofilm on the oxygen-rich surface of the MABR spiral membrane. The biofilm, in return, drives the simultaneous nitrification and denitrification process that makes MABR modules one of the most efficient, robust, and compact wastewater treatment technologies available.

Contact Fluence to learn more about how MABR can harness biofilm to improve your wastewater treatment operation.