Free online tool uses ISO 21939-1:2019 to help you estimate the energy used in a wastewater treatment process

By entering values into Fluence’s wastewater treatment energy consumption calculator, you can quickly and easily estimate the amount of energy used for industrial water reuse.

In the past, there was no single trusted way for engineering consultants and utility owners to compare energy efficiency claims by various wastewater treatment manufacturers. Traditional measurement methods focused on different parameters and expressed energy in different formats leading to unreliable and inconsistent results.

To solve this problem, experts created the ISO 21939-1:2019 standard, a standardized means to express energy consumption for biological wastewater treatment processes. This method accounts for all pollutants and normalizes the calculation of energy consumed to allow meaningful comparisons among different facilities and technologies.

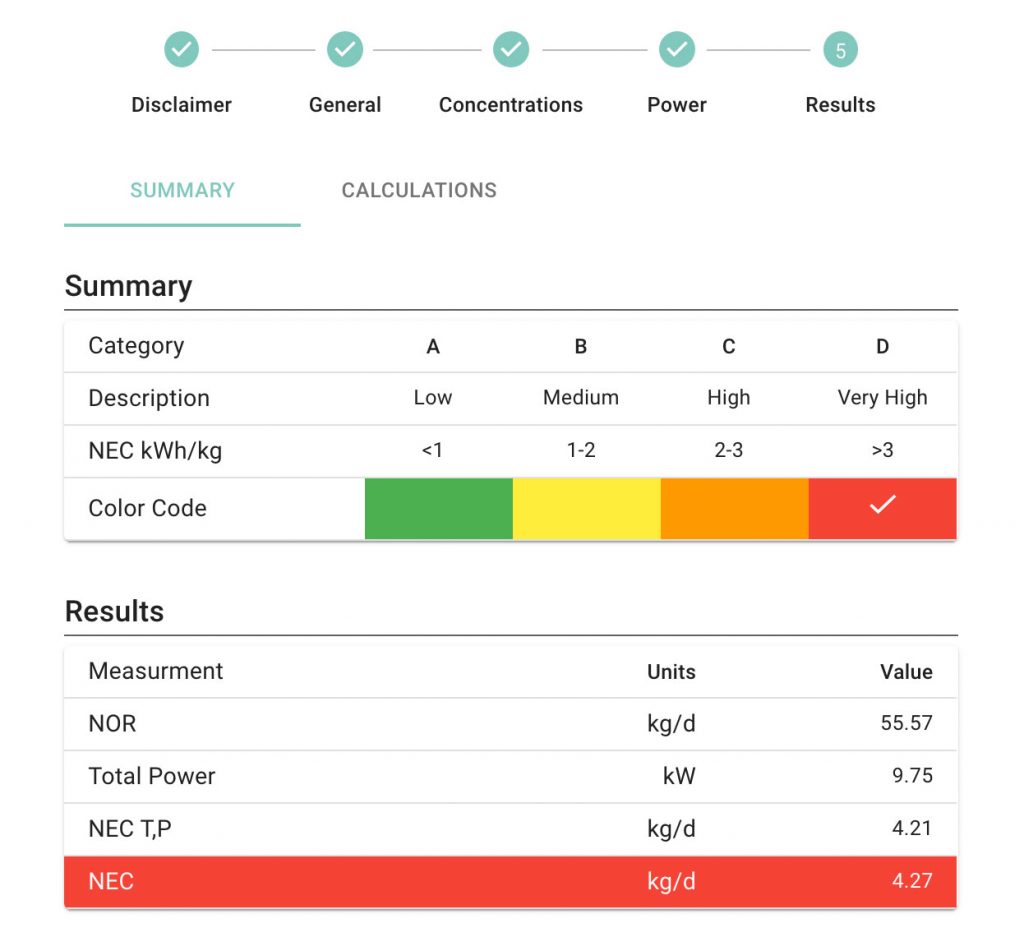

To make the standard more accessible, Fluence has created a free online calculator for measuring energy consumption of a wastewater treatment system — also referred to as a Normalized Energy Consumption (NEC) Calculator. The calculator automatically applies the ISO 21939-1:2019 formula to your system’s data, calculating an estimate of your process’ energy use.

You can try it free here. No user information is saved by the calculator.

Why is the standard important?

One of the experts involved in the development of the ISO 21939-1:2019 standard was MABR inventor Ronen Shechter, who explained its importance:

Energy consumption for wastewater treatment is a significant operational cost and reducing it is a global sustainability goal. However, reporting on it is not regulated or standardized, making comparisons difficult. For example, ‘consumption per unit volume’ disregards differences in pollutant removal capacity in different cases, and ‘consumption per unit mass BOD removed’ disregards nutrient removal. This led to the idea of creating a standardized metric, one that would include all factors, and to define uniform battery limits for the wastewater treatment process.

Energy-Saving Wastewater Treatment Technology

If you find your wastewater treatment is using too much energy, for instance in areas without adequate electrical service, Fluence has cutting-edge solutions that can substantially decrease power use while producing an effluent suitable for non-potable reuse.

Fluence’s modular Aspiral™ line delivers wastewater treatment in a compact, pre-engineered shipping container. Aspiral™ can be installed and commissioned in a matter of weeks, delivering top-quality effluent that exceeds both California Title 22 and China’s Class 1A standards for agricultural water reuse.

Its low-odor, low-noise operation allows you to place an Aspiral™ plant right at the source of wastewater, eliminating the need for long pipelines to remote wastewater treatment plants. Such pipelines are expensive to build, maintain, and operate.

Aspiral™ treatment is based on the energy-efficient membrane aerated biofilm reactor (MABR), which returns superior energy efficiency numbers under the ISO 21939-1:2019 standard due to its use of passive aeration.

Fluence’s MABR technology can also be used to upgrade plants. MABR-based SUBRE units are submerged in existing chambers to increase capacity without expanding your footprint.

After you determine how your biological process energy use measures up with our wastewater treatment energy consumption calculator, contact the experts at Fluence to learn how you can streamline your process with an eye toward energy efficiency.