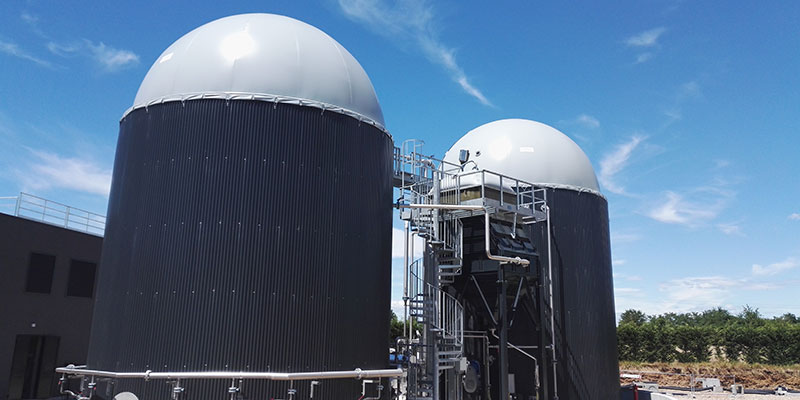

Anaerobic Digestion

Fluence has decades of experience providing waste-to-energy solutions for wastewater, and was recently named a Top Waste to Energy Solutions Provider for 2023 by Energy Tech Review.

Fluence specializes in anaerobic wastewater treatment, or anaerobic digestion, a biological treatment process that uses microbes to biodegrade organic matter (feedstock) in an oxygen-free tank, treating challenging, high-organic-load wastewater streams and generating valuable products in the process.

Top Benefits

- Reducing disposal cost by >70%

- Generating clean, renewable energy

- Generating biosolids with high agronomic value

- Qualify for tax credits up to 50%

- Increasing revenue

- Increasing your ROI

Industries Supported

- Food and beverage production

- Sewage and sludge slurries

- Livestock operations

- Paper and pulp manufacturing

- Biofuel and sugar refining

- Dairy

Fluence is an anaerobic wastewater treatment provider with more than 30 years in the industry. With its Water Management Services, Fluence can provide plants at no upfront cost and remain with them, providing operations and maintenance for the long haul.

Anaerobic Digestion Case Studies

Waste-to-Energy Upgrade for Chicken Processing WWTP

Italian food processors Amadori SpA cut operations costs with a custom-designed biogas plant from Fluence that produced an effluent compliant with strict European Union guidelines.

Wastewater and Waste-to-Energy for Candied Fruit Manufacturer

With tight space limitations, Fluence installed a biogas plant without a break in production at Vitalfood-Italcanditi, a manufacturer of glazed chestnuts, candied fruit, jams, and other food, bakery, and dairy industry staples.

Waste-to-Energy for a Pharmaceuticals Producer

Fluence expanded and refurbished Italian Novamont subsidiary Mater-Biotech's biochemical facility with water treatment, wastewater treatment, and waste-to-energy in three treatment trains.

Anaerobic Wastewater Treatment for Confectionary

Italian confectionary company Dolcissimo reached out to Fluence to install a new treatment train with tight space limitations. The Fluence system now generates biogas, cuts COD and nitrogen, and diminishes solid sludge by 70%, meeting challenging effluent targets.

Dairy Feeds Biogas Plant With Whey

Wastewater Treatment Upgrade Helps Paper Manufacturer Meet Environmental Standards & Save on Operating Costs

Anaerobic Digestion FAQ

When is it best to use anaerobic digestion?

Can anaerobic digestion be profitable?

The size of the digester and hydraulic retention times also influence viability. Larger digesters allow long hydraulic retention times for top biogas yields, while it may be harder to break even with smaller digesters. When there is inadequate feedstock, nearby operations may pool feedstocks to keep a large digester busy or employ numerous other anaerobic variations to boost productivity.

Because of a global fertilizer shortage, nearby agricultural operations may be willing to pay for an AD operation's nutrient-rich liquid digestate, the sludge left over after treatment. Liquid digestate is routinely applied directly to fields, and an additional dewatering process can create more stable dry fertilizer products. Anaerobic digestion also has the potential for electrical and thermal energy generation, renewable natural gas generation, and even hydrogen generation.

Are there tax credits for AD?

In the United States, the landmark Inflation Reduction Act (IRA) of 2022 was passed to slow inflation by investing in American energy production and clean energy. It established a stand-alone Investment Tax Credit (ITC) of 30% to offset CAPEX for the construction of qualified biogas property systems.

Projects that started construction in 2020 through October 2022 are entitled to the full 30% credit, while projects that start later must meet wage and apprenticeship rules to get the full credit. Qualified biogas projects typically start at 6% for basic biogas utilization, and quickly increase to 30% with certain wage requirements. An additional 10% can be realized for projects that use domestically sourced material, and another 10% is tied to selected energy sites.

What exactly is a 'qualified biogas property'?

Under the IRA, a "qualified biogas property" is a property with a system that converts organics/biomass into gas at 52% methane or higher, concentrates it to that strength, or cleans and conditions the gas. The gas must be recovered for sale or productive use. Construction of qualified biogas property must be started by December 31, 2024.

How much energy can AD produce?

While there are too many variables to give a fixed answer, average wastewater contains five times more energy than is needed to power the wastewater treatment process. High-load streams may contain even more. Waste-to-energy systems frequently use recovered energy to fuel the treatment process, with energy left over to generate electricity, or fuel other industrial processes or vehicles. Biogas from anaerobic digestion can also be sold externally. In the European Union, the market for biogas is fully mature, with biomethane – refined biogas – accounting for 17% of the gas used for road transport on the continent.

Can anaerobic digestion lower municipal utility bills?

Frequently, operations that produce high-strength wastewater rely on municipal wastewater treatment systems, which may raise bills when effluents overstress treatment plants. Many Fluence anaerobic digestion clients initially explored it due to excessive utility costs and have been able to realize significant savings on municipal wastewater treatment.

And, when biogas generated on-site by digesters is used to fuel boilers and electrical generators to power processes, it lowers electricity and natural gas bills.